Installation, Commissioning & Service

Our intense contribution in terms of quality and on-time transmission at each stage of an enterprise and cluster responsibility gives our customers a sense of comfort and confirmation. Basically, we focus on prioritizing issues and maintaining accurate documentation at each stage.

- We will assess the needs of our customers at ENACT.

- we are designed for generating optimized results

- Installation is finished in compliance with all performance specifications

- Our Systems are tested and balanced

- refrigerant and combustion are measured and adjusted

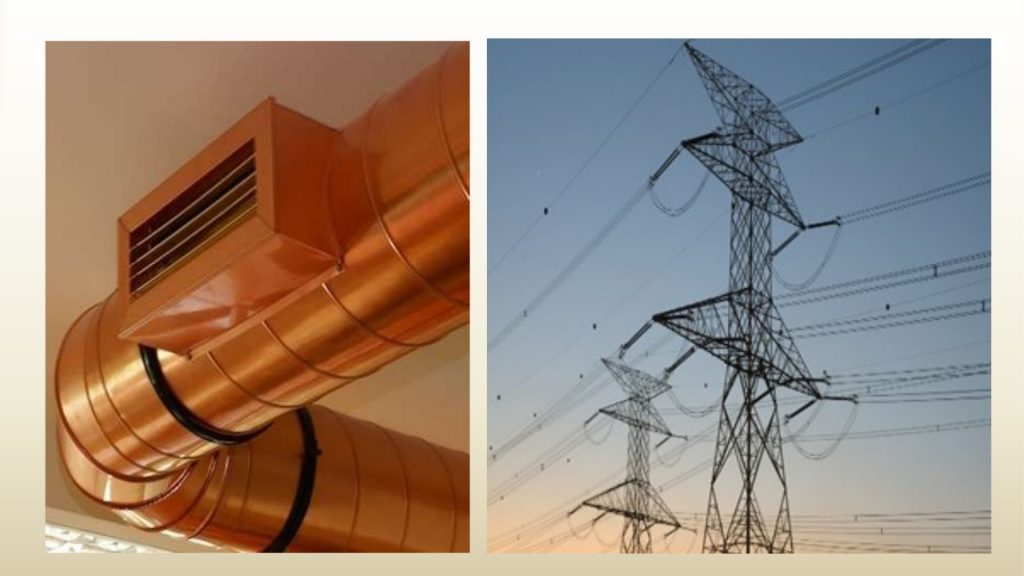

- Rating the quality and performance of the HVAC system

- Assurance of safety via inspection

- The building’s performance is verified.

- Instalation of transmission and communication towers

LOW VOLTAGE POWER & DISTRUBUTION PANELS

Power Control Centre is used for distribution and control of various power source used in industry. Normally Power Control Centers is installed near power source hence fault level is low.

To distribute the power through the panels, our Power Cum Motor Control Centre (PMCC) range is used. It is then distributed to the various loads of the engine located in different parts of the factory system.

DC Starter Panels are used to provide consistent power supply from the starting current, without disturbances or interference. These panels are manufactured using the latest technology in accordance with established industrial standards.

An electric distribution board for a commercial building is an essential part of an electrical installation. It is intended to distribute the electricity supply equally across the building via different circuits. The incoming power must be monitored in this way to avoid overloads

How intelligent is the motor control center (MCC)? Motor control centers monitor and control the operation of electrical load collection. This device becomes intelligent when integrated with communications and smart devices – allowing an active panorama of the power system.

Local Control Stations (LCS) or otherwise referred to as Push Button Stations (PBS) are an integral part of the control gear for any heavy industrial scenario and, depending on the application of the system, are used to control the machinery either locally by the front line engineer or remotely from the control room

The Power junction box is a housing for electrical connections. Junction boxes protect electrical connections from the weather and prevent accidental electrical shocks from occurring.

MEDIUM VOLTAGE PANELS

The main distribution point for electrical circuits in your home is the electrical circuit breaker panel. It normally provides between 100 and 200 amps of power, depending on the rating of the panel. Power comes from the lines of the utility company to your home. It flows through an electrical meter that records your electricity usage, and then into the panel. Some systems are also equipped with a large disconnect switch between the meter and the panel.

The LAVT panel is a cube that houses a Lightning Arrester Voltage/Potential Transformer for a Phase Isolated Bus Duct. Lightning arrestor is there to provide protection against any voltage surges, hence the name of the lightning arrestor, a device that safely diverts any voltage surge away from your plant and thus helps protect your equipment against overvoltage conditions.

Lightning Arrestor Surge Capacitor Potential Transformer. The surge capacitor is mostly used to decrease (minimize) voltage fluctuations in the grid due to lightning and bad weather conditions

Automatic Power Factor Control or APFC Control Panels are designed in order to improve the power factor. APFC is an automatic power factor control panel that is used to improve the power factor when necessary by turning on and off the desired capacitor bank modules automatically.

CONTROL, RELAY, PROTECTION & AUTOMATION PANELS

Relay and metering panels are used for remote control of the HT breaker. It comprises multiple protective relays required to handle the system and for the measurement of electrical parameters.

A user interface is required for any complex piece of machinery to allow the users can monitor its operations, inspect for efficient operation, and act immediately when required. Machines seize up, hold back, accelerate or typically vary in performance on the basis of a wide range of factors such as fatigue, weather conditions, and depreciation of components and parts.In electrical machines, such as generating units, these distinct changes constitute an electrical signal. These transmissions can be constructively produced to regulate the machine’s performance.

Synchronization panels are designed and used primarily to meet the requirements of the power system. For two or more generators or breakers, these panels function both manually and with an automatic synchronization function. They are commonly used in generator synchronizing and offering

A desk with panels displaying information and showcasing controls used by a technician or a group of specialists to deal with entities and their qualitative research features. A control console is the main unit of the position of the operator and one of the fundamental means of man-machine interaction.

Synchronization panels are designed and used primarily to satisfy the requirements of the power system. For two or more generators or breakers, these panels function both manually and with an automatic synchronization function. They are widely used in generator synchronization and multichannel solutions

CONTROL, RELAY, PROTECTION & AUTOMATION PANELS

One of the most important and efficient types of control panels is the Programmable Logic Controller (PLC) or PLC Automation Panel. Which are typically used in various fittings for electronic and electrical circuits

The Programmable Logic Controller –Turbine Generator(PLC-TG) drive is “off the shelf” Hydraulic solenoid valves The PLC-TG is suited for small and medium sized Installation with basic Requirements for Speed Regulation.

Instrumentation Control Panels are designed to detect and monitor the temperature, stream, current and pressure levels of the related field equipment that are integrated to it.

SCADA (Supervisory Control and Data Acquisition) is a system aimed at monitoring and controlling field devices at remote locations. … SCADA has an unified approach that integrates the entire area and controls it. This monitoring system collects process data and sends control of the orders to the process.

In AC motor speed control applications, Enact Projects offers Variable Frequency Drive (VFD) panels or simply drive panels. By changing the motor input frequency along with the voltage, VFD Panels control motor speed. In order to reduce costs, VFD panels control the electricity consumption of AC motors.